Thermomechanical Analysis (TMA)

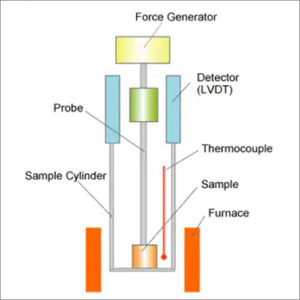

Thermomechanical analysis (TMA) is to study the dimensional change of materials under a constant stress within a temperature regime.

- Description

| Testing Method | Thermomechanical Analysis (TMA) |

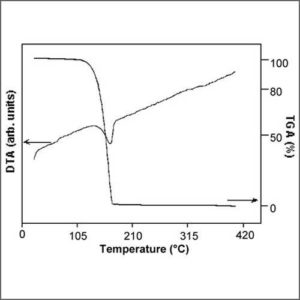

| Description | Thermomechanical Analysis (TMA) is a technique to study the dimensional change of a material over a predefined temperature segment whilst the material is applied a constant stress. Many materials undergo changes of their thermomechanical properties during heating or cooling. For example, phase changes, sintering steps or softening can occur in addition to thermal expansion. Typical application domains of TMA include plastics and elastomers, paints and dyes, composite materials, adhesives, films and fibers, ceramics, glass, metals, and composite materials.

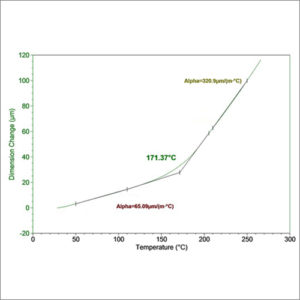

A special related technique is to measure the linear thermal expansion of a sample with negligible force acting on the sample while it is subjected to a constant heating rate. The change of the specimen length is electronically recorded as a function of temperature. The coefficient of thermal expansion (CTE) can be calculated from the recorded data.

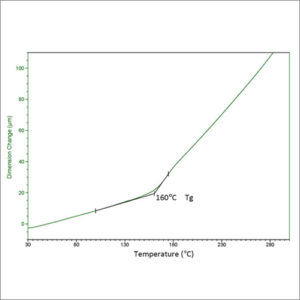

Thermomechanical Analysis (TMA) is used to determine the glass transition temperature of a specimen. TMA records the change in dimension of a specimen observed when the material is subjected to a constant heating rate through its glass transition. This change in dimension associated with the change from vitreous solid to amorphous liquid is observed as movement of the sensing probe in direct contact with the specimen and is recorded as a function of temperature. The intersection of the extrapolation of the slope of the probe displacement curve before and after the transition is used to determine the glass transition temperature.

Another related technique is to measure the distortion temperature of a specimen. The specimen of known dimensions is tested in three-point bending mode. A known stress is applied to the center of a test specimen supported near its ends, as it is heated at a constant rate from ambient temperature to the upper temperature limit for the material. The deflection of the test specimen is recorded as a function of temperature. The temperature at which a predetermined level of strain is observed in the test specimen is analyzed as the distortion temperature. |

| More Information | Wikipedia: Thermomechanical Analysis |